Search results

-

MB7137 I2CXL-TrashSonar-WR

Ranges from 20cm to 350cm with up to 40Hz read rate. I2C interface. Reports range to closest.

Regular price From

$84.65Regular priceUnit price per -

BlogBlog

-

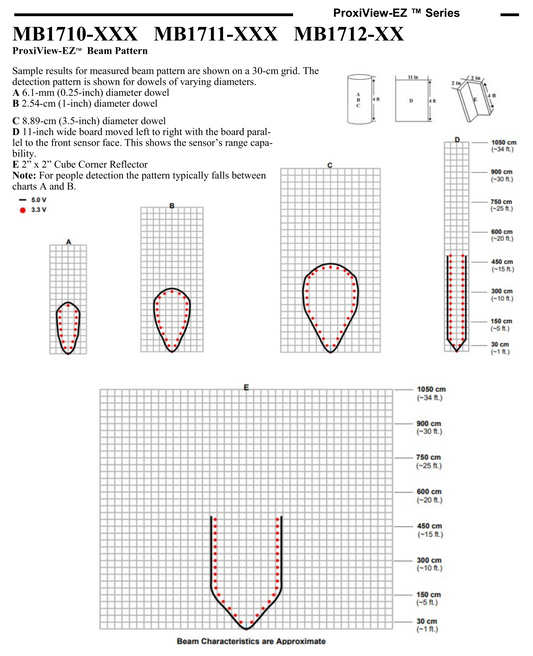

Kiosk Sensor - 5m Range, 1mm Resolution - Combination Ultrasonic and IR Proximity - ProxiView-EZ

The 5m Ultrasonic + IR Kiosk Proximity Sensor is a compact, low-voltage IR + ultrasonic sensor designed for kiosk and people-detection applications. By combining optical proximity sensing with ultrasonic ranging, it offers dependable object detection from the front face out to 5 m, with 1 mm resolution and range measurements from 30 cm to 5 m.

Each sensor auto-calibrates for temperature, supply voltage, and target characteristics, delivering stable readings even in acoustically noisy indoor environments. USB and QWIIC-I2C variants simplify connection to computers and embedded systems while keeping the sensor dimensions under two cubic inches for easy mounting.

Regular price From

$69.95Regular priceUnit price per -

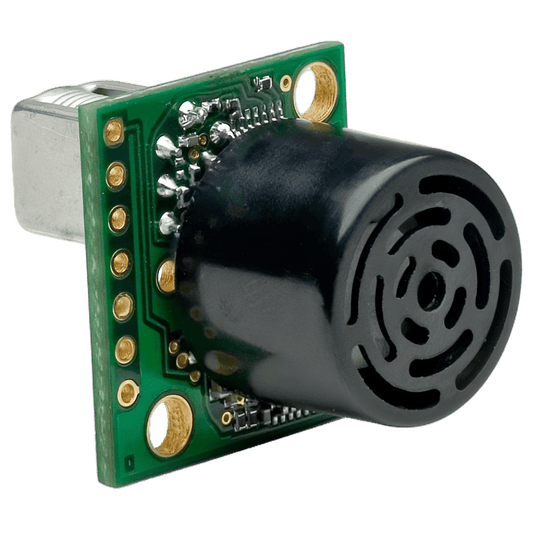

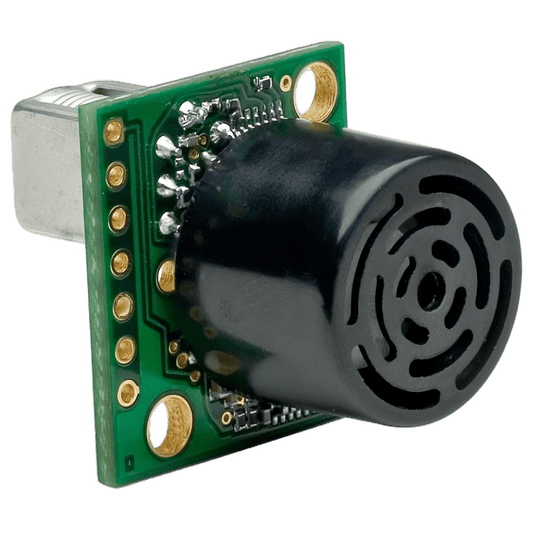

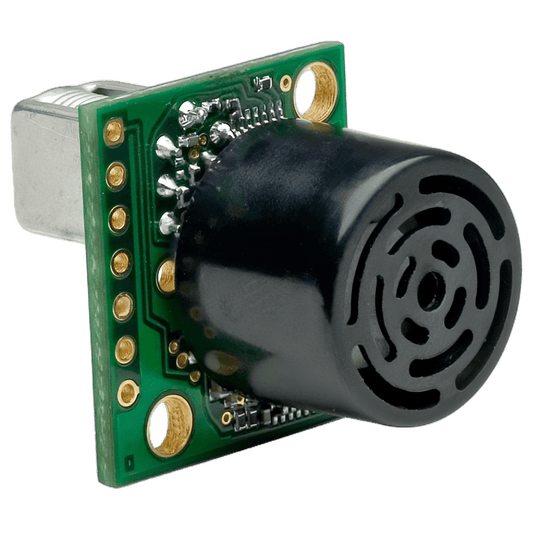

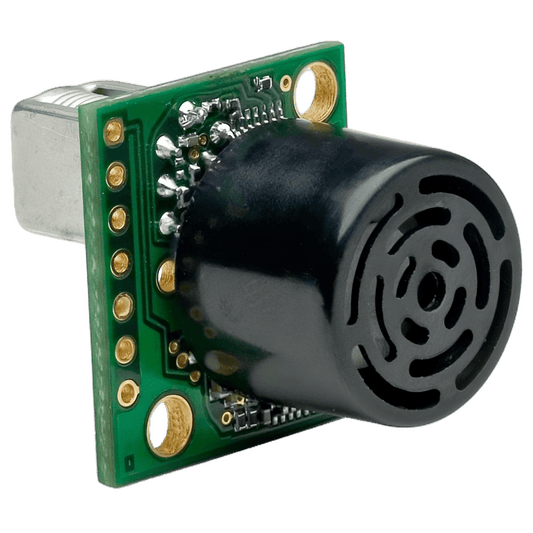

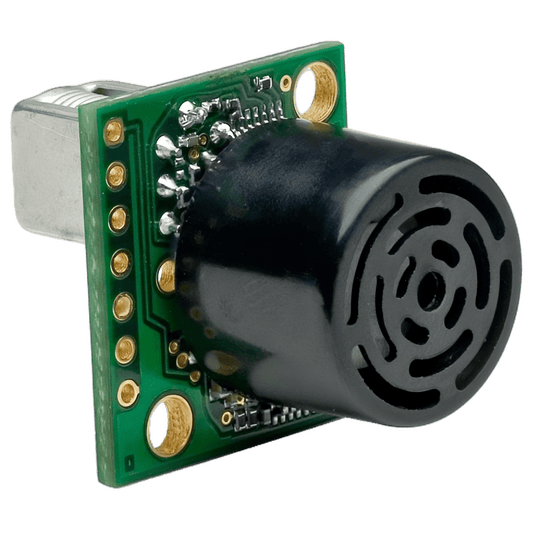

MB1242 I2CXL-MaxSonar-EZ4

Ranges from 20cm to 765cm with up to 40Hz read rate. Narrowest detection field. Highest noise tolerance.

Regular price From

$32.65Regular priceUnit price per -

MB7040 I2CXL-MaxSonar-WR

Ranges from 20cm up to 765cm* with up to a 40Hz read rate. The sensor features I2C output and reports the range to the closest target.

Regular price From

$84.65Regular priceUnit price per -

MB1202 I2CXL-MaxSonar-EZ0

Ranges from 25cm to 765cm with up to 40Hz read rate. Widest detection field. Excellent for people detection.

Regular price From

$32.65Regular priceUnit price per -

MB1222 I2CXL-MaxSonar-EZ2

Ranges from 20cm to 765cm with up to 40Hz read rate. Mid-width detection field. Balance between sensitivity and side object detection.

Regular price From

$32.65Regular priceUnit price per -

MB1232 I2CXL-MaxSonar-EZ3

Ranges from 20cm to 765cm with up to 40Hz read rate. Narrow detection field. High noise tolerance.

Regular price From

$32.65Regular priceUnit price per -

MB1212 I2CXL-MaxSonar-EZ1

Ranges from 25cm to 765cm with up to 40Hz read rate. Wide detection field. Excellent for people detection.

Regular price From

$32.65Regular priceUnit price per -

MB8000 ToF MaxLidar™ Laser

MaxLidar™ MB8000: Precision LiDAR, 25m range, ±6 cm accuracy, 1kHz refresh rate, auto dust cleaning, IP5X-rated, Class 1 safe laser, industrial-grade, 3° FoV, low-power, UART/I2C interfaces.

Regular price From

$399.95Regular priceUnit price per