Collapsible content

Description

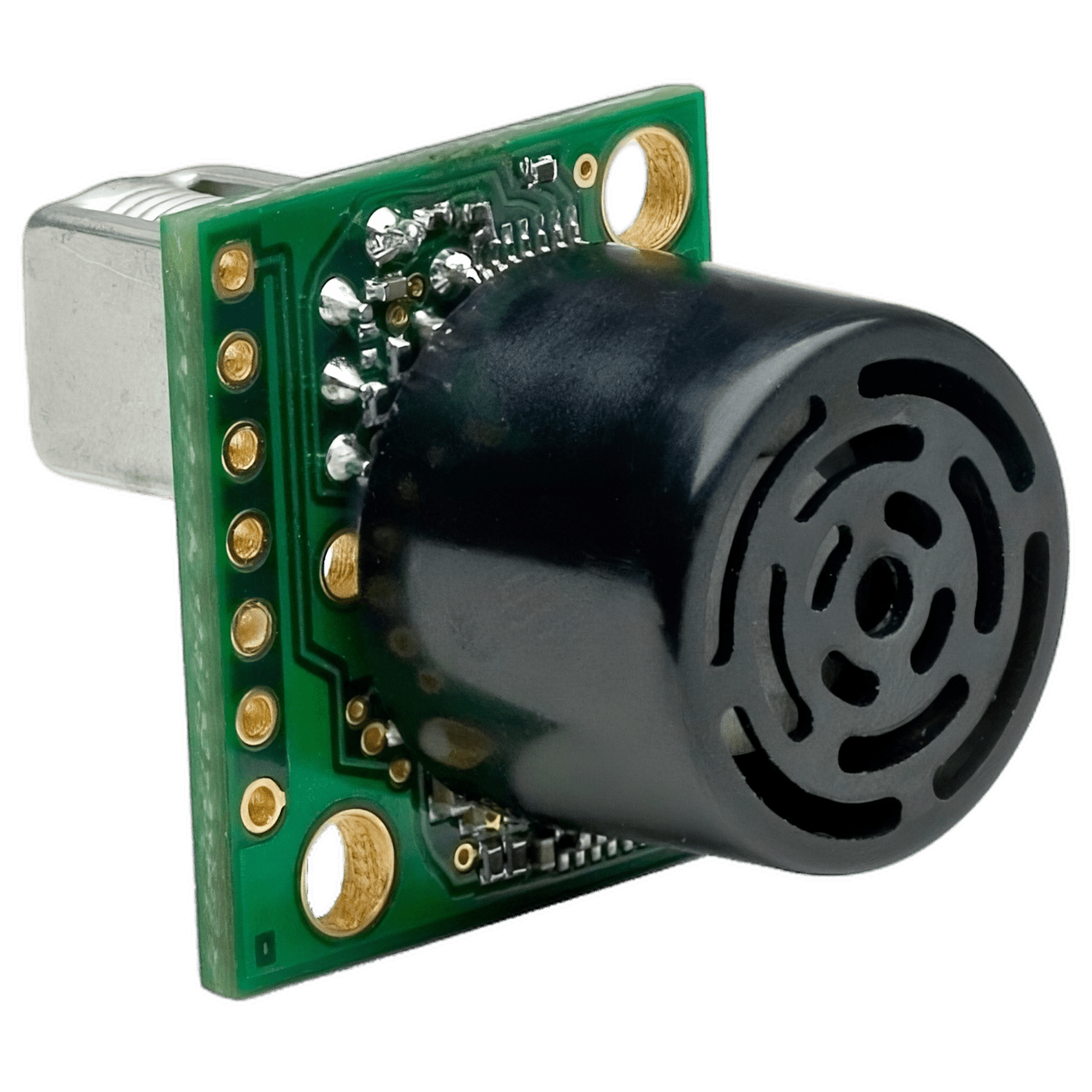

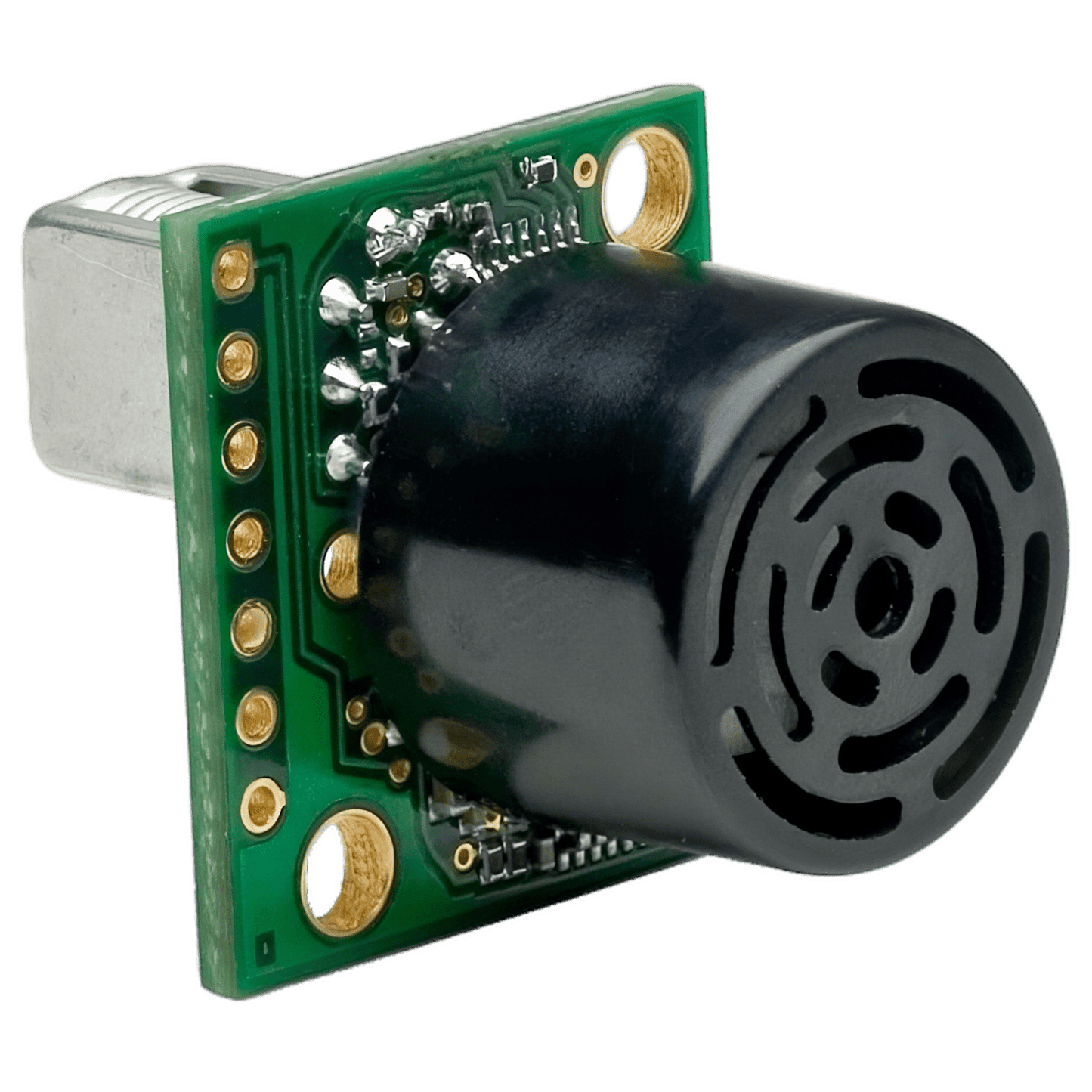

Features of the MB1202, I2CXL-MaxSonar-EZ0, include centimeter resolution, the widest and most sensitive beam pattern of any unit from the I2CXL‑MaxSonar‑EZ sensor line, short to long distance detection, range information from 25cm to 765cm, up to a 40Hz read rate, and an I2C interface.

This makes the MB1202 an excellent choice for use where high sensitivity, wide beam, or people detection is desired.

The MB1202 from the I2CXL‑MaxSonar‑EZ line of sensors is a very small, less than one cubic inch, ultrasonic sensor component module. This sensor comes with mounting holes provided on the circuit board for easy installation in nearly all applications.

In addition, the MB1202 offers virtually noise-free distance readings through the use of high-output acoustic power combined with continuously variable gain, real‑time background automatic calibration, real‑time waveform signature analysis, and noise rejection algorithms. This holds true even in the presence of many of the various acoustic or electrical noise sources.

Specs

- Resolution of 1 cm

- Up to 40Hz reading rate

- Simple I2C bus interface

- Easy control of multiple sensors

- Control up to 127 sensors using two wires

- 42kHz Ultrasonic sensor measures distance to objects

- RoHS Compliant

- Virtually no dead zone, objects closer than 25 cm range as 25 cm

- Operates from 3.0-5.5V

- Low 4.4mA average current requirement

- Small, lightweight module

- Designed for easy integration into your project or product

- Operational Temperature from 0C to +65C (32F to +149F)

- Real-time automatic calibration (voltage, humidity, ambient noise)

- Firmware filtering for better noise tolerance and clutter rejection

- 20+ Years Mean Time Between Failure

- Widest beam pattern in I2CXL-MaxSonar-EZ sensor family

Documentation and CAD files

Documents

| I2CXL-MaxSonar-EZ Datasheet |

| Using an I2C-MaxSonar With an Arduino |

| RoHS Declaration of Conformity |

| CE Declaration of Conformity |

Product 3D Models

XL-EZ CAD Files

Part Numbers

All MaxBotix part numbers are a combination of a six-character base followed by a dash and a three-digit product code. The following table displays all of the active and valid part numbers for this product.

Active Part Numbers

Recommended Accessories

-

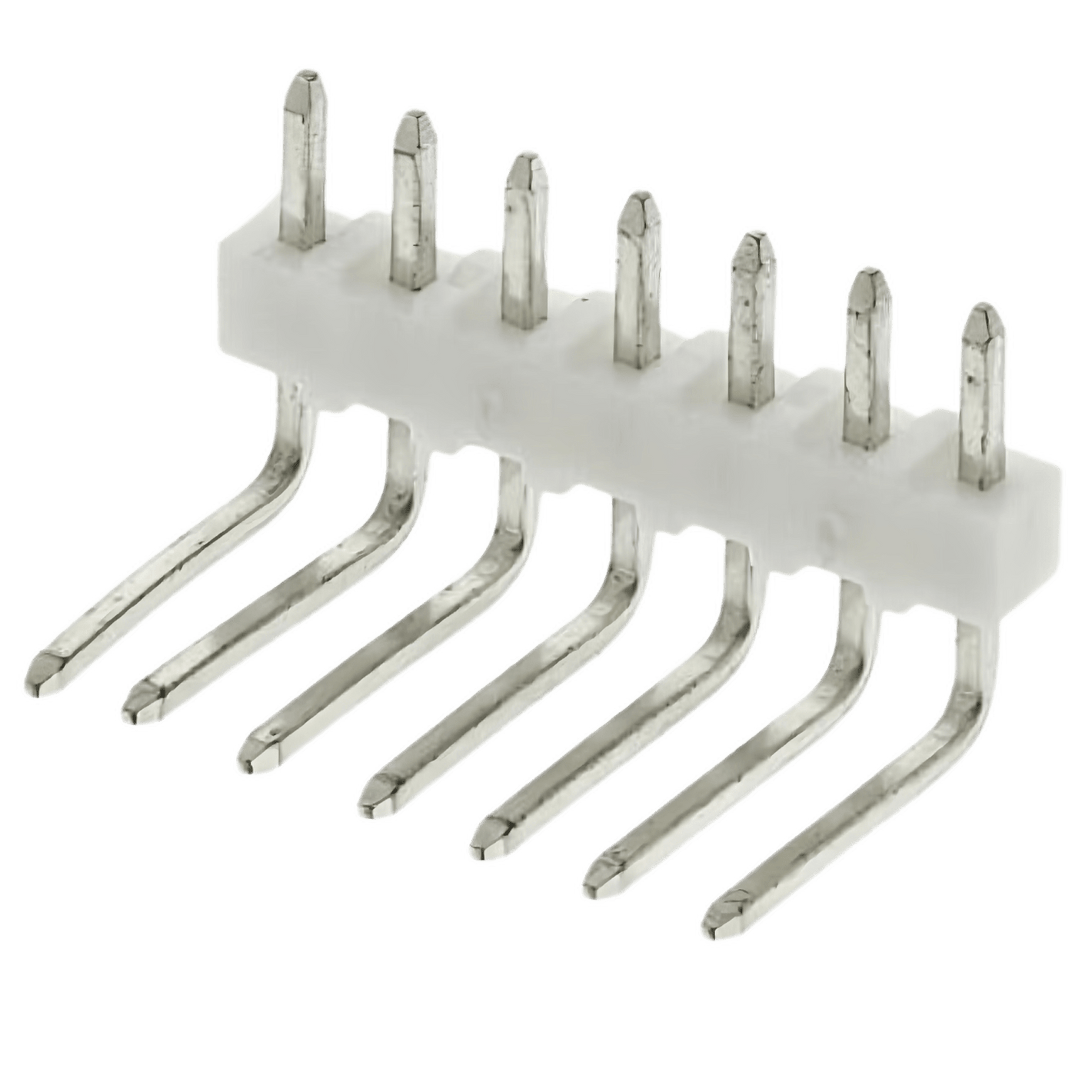

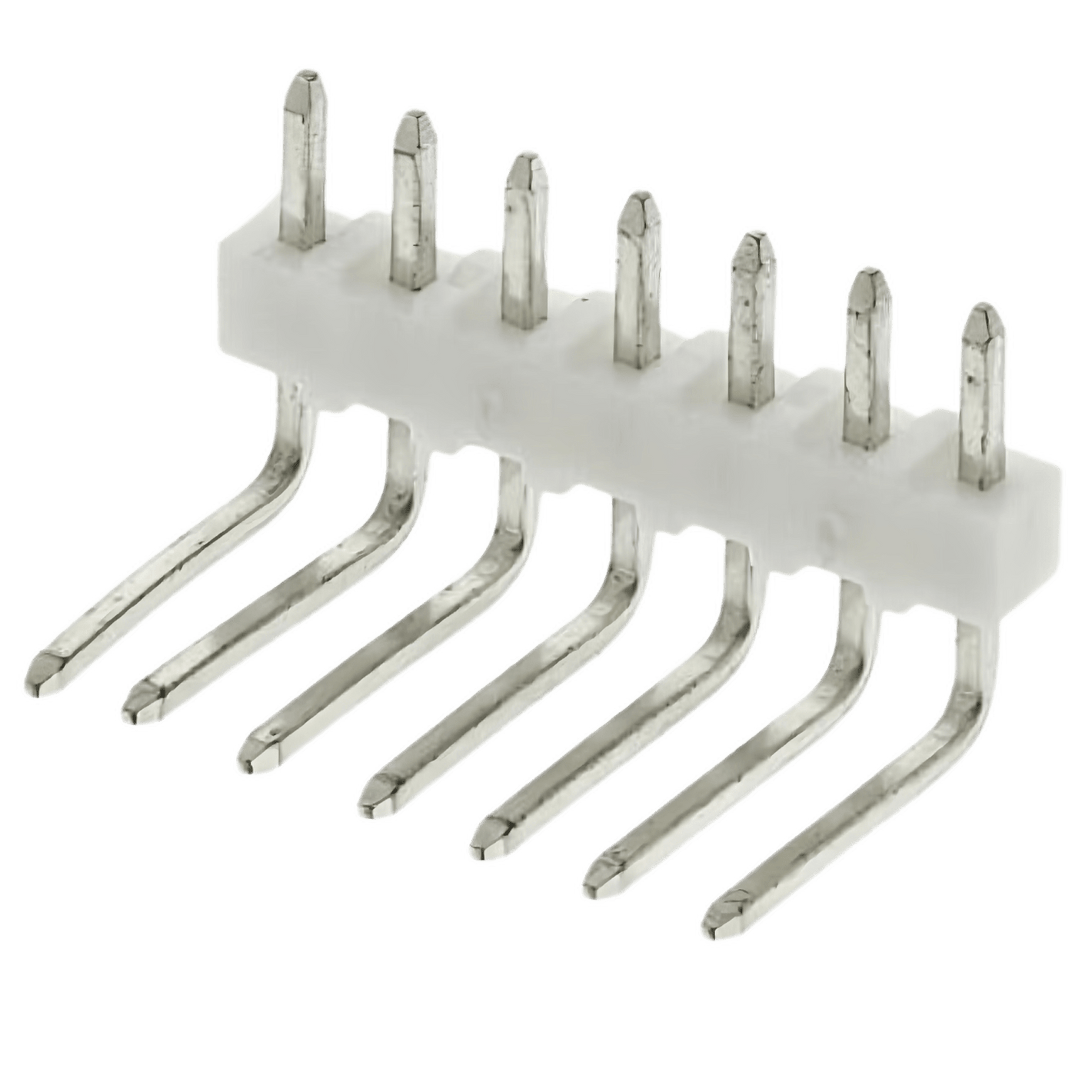

Pin Header (90 Degree 7 Pin) Attached

View AccessoryConnector Header Through Hole, Right Angle 7 position 0.100″ (2.54mm)

-

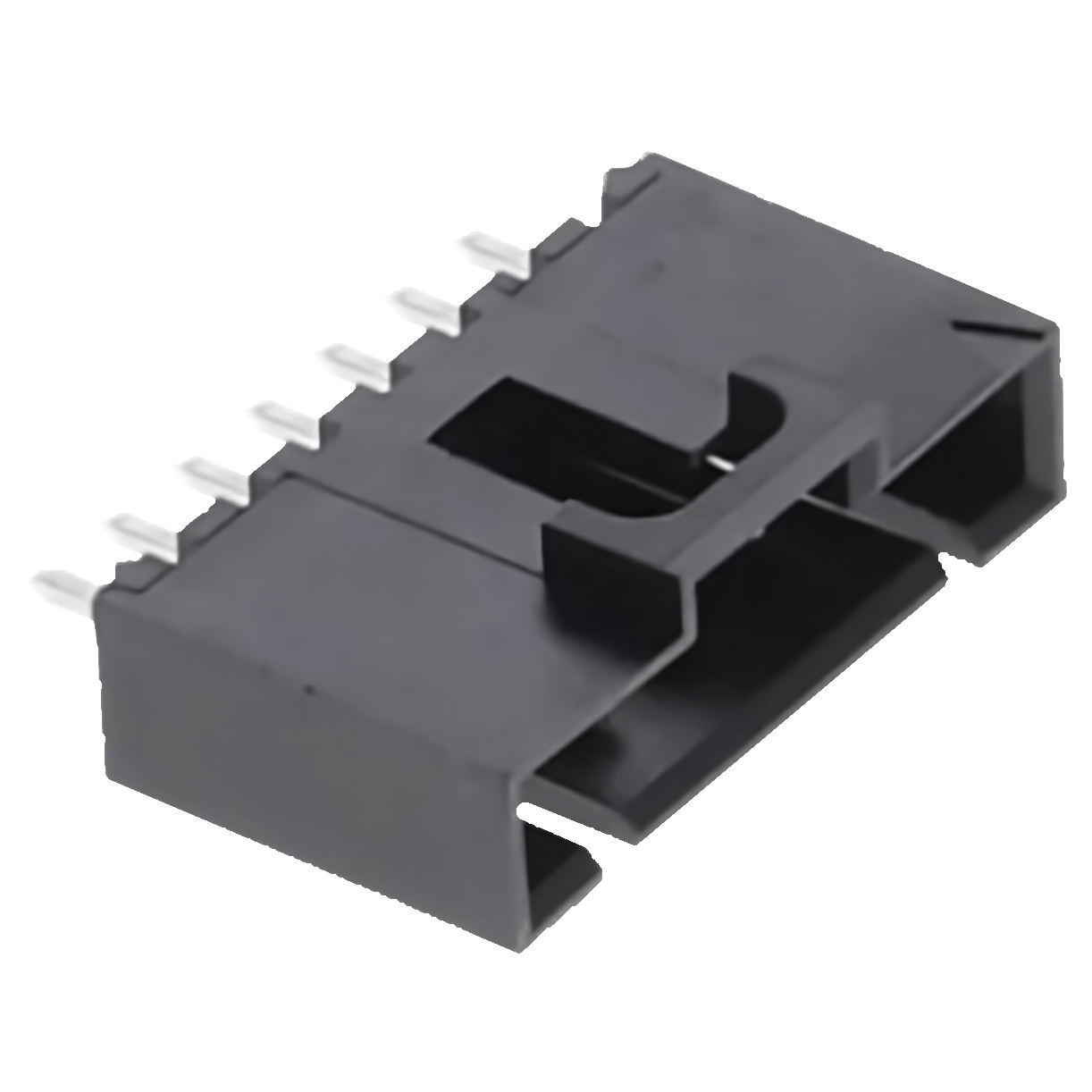

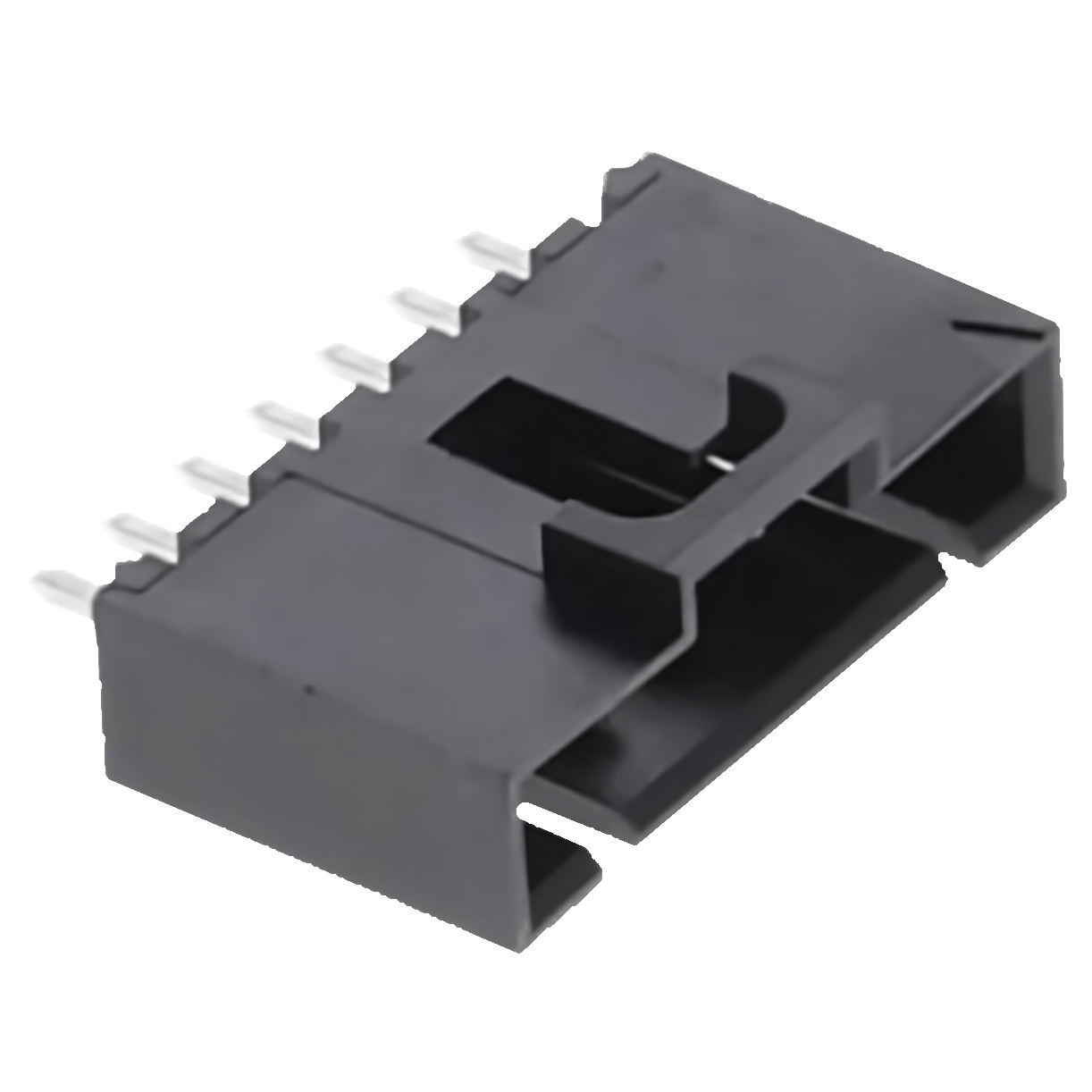

Pin Connector (7 Pin) Attached

View AccessoryConnector Header Through Hole 7 position 0.100″ (2.54mm)

-

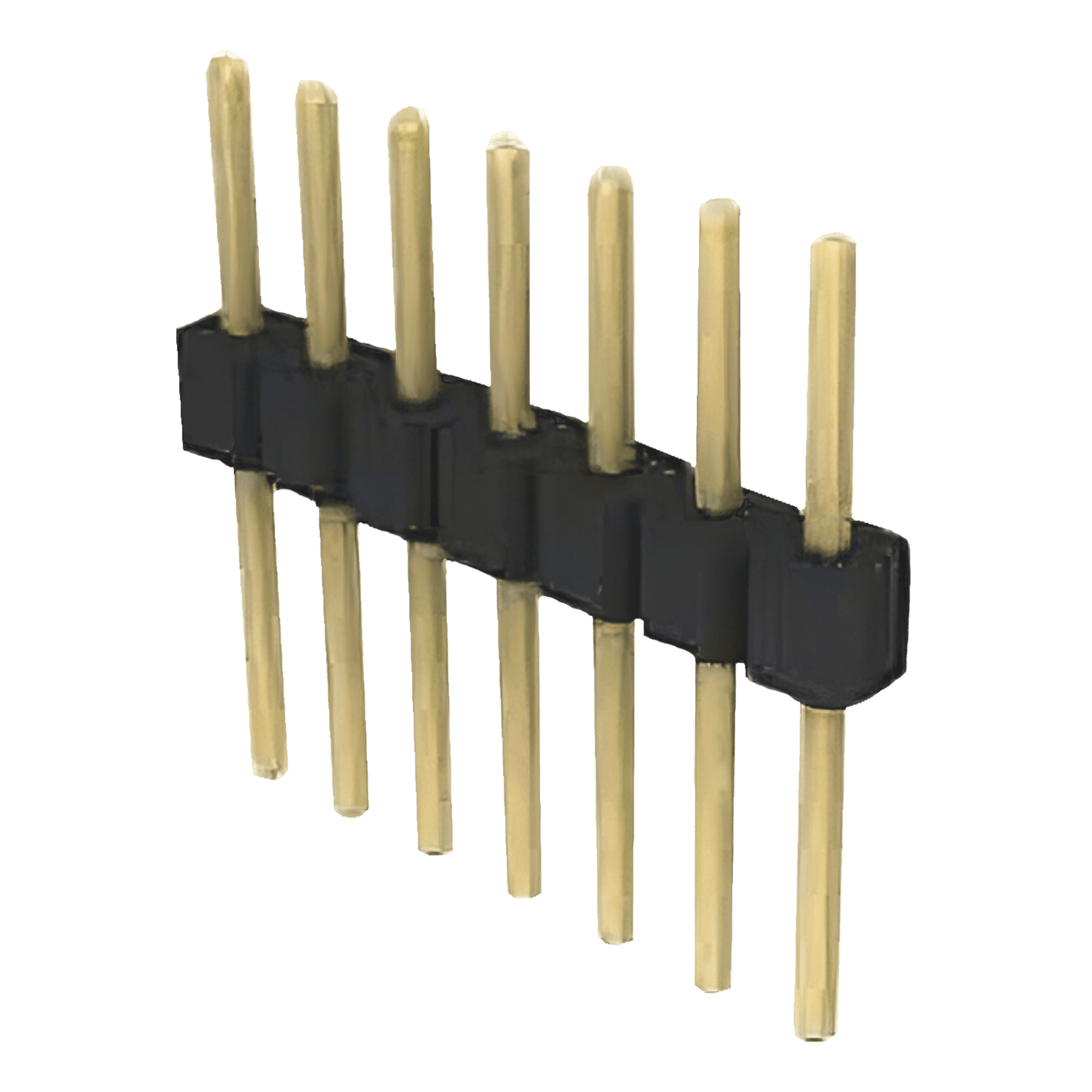

Straight 7 Pin Connector Attached

View AccessoryConnector Header Through Hole 7 position 0.100″ (2.54mm)

-

-

-

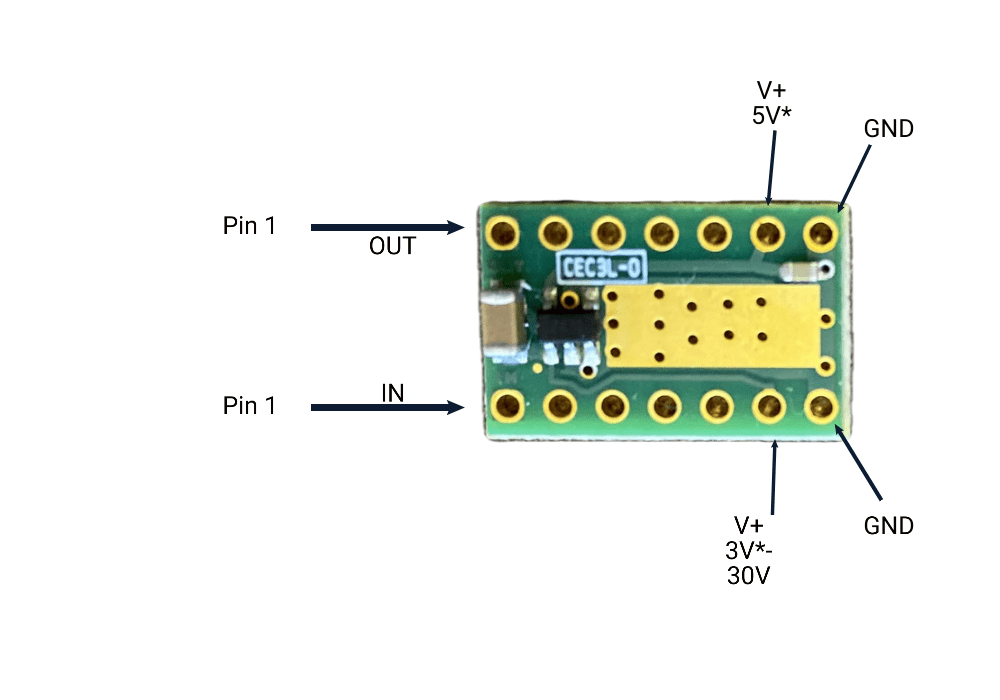

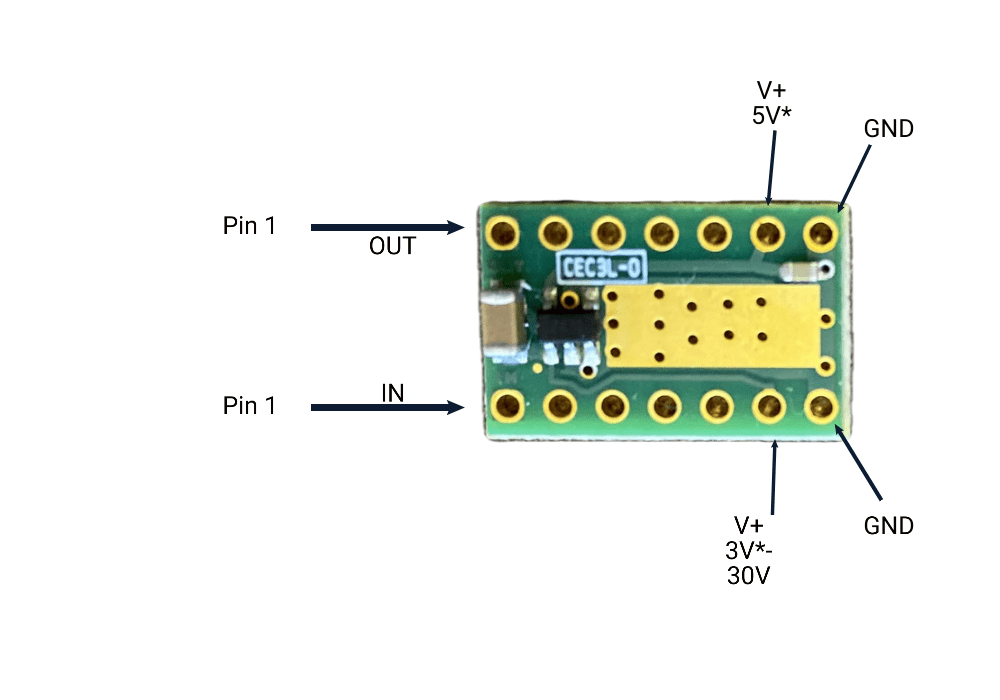

MB7986 Voltage Regulator

View AccessoryThe voltage regulator is used to automatically regulate voltage inputs from 3V to 30V.