MaxBotix Inc., Continues to Expand

Production began in 2004 in the office of the owner’s house. With exponential growth in the first three years, the company made their first move in 2007 followed by yearly moves to bigger spaces over the next three years.

MaxBotix Inc., headquarters and production operations moved to a larger facility to meet increased sales demand. This exponential growth required space, vision, and forward thinking. Leading this mindset is Bob Gross, CEO.Corporate Mission Statement:

We believe in products that make a difference. Our goal is to design and manufacture sensor technology that drives innovation and creates exciting new industries and applications.

Our Goal of Doubling Yearly Required a Huge Leap of Faith

With four moves in as many years, Gross needed to look forward. His goal for the company was to continue doubling revenues yearly. This goal was achievable based on the previous year’s numbers, so Gross had to look to the future, not the immediate but to long term. In 2012, the owners purchased 23.5 acres that included a horse barn and riding arena totaling 22,000 sq ft.

Industry Vision:

Creating vision for the future.

Original Use of 10,000 sq ft

The original building had a business with some established work areas, bathrooms, offices, and a break room. Construction of the first 10,000 sq ft in 2013 completed the office and engineering areas (~2,500 sq ft) and a manufacturing production area (~7,500 sq ft).

This newly constructed area provided the necessary space to grow and expand operations for the next three years. The manufacturing production area was set up with testing stations and workstations. The receiving and shipping area set up dedicated space and storage. In 2015, three new machines were added to aid in the speed of production. Additionally, the company created dedicated space and dedicated departments.

MaxBotix Had Record Year in 2015

2015 also brought a new accolade. We were accepted to be on Inc. 5000’s list of fastest growing companies. We showed an 87% increase from 2011 to 2014. With the new year, comes new numbers. Our projected growth from 2012 to 2015 is 212%. With such an increase comes the need for more space.

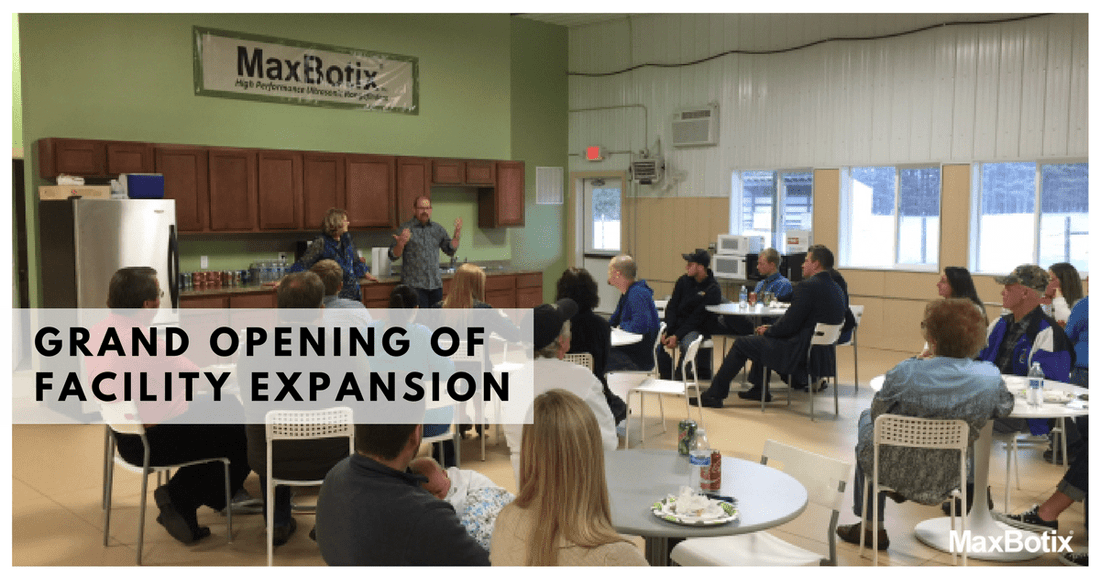

The remaining 12,000 sq ft began construction during the Fall of 2015. This area was originally the riding arena for the equestrian center. Construction began with a bigger septic system to handle the additional six bathrooms and the new kitchen area. The new break room is open to the rest of the area with windows for viewing of the many wildlife species that walk the fields. A concrete floor was poured and electrical and networking wires ran. The final phase is to plan for machine and product expansion.Grand Opening!

On April 19th, we welcomed our supporters to join us for the Grand Opening of Facility Expansion. Bob and Nita Gross gave a tour of the build out and their vision for the space.

We continue to be in awe of the support from our community, our employees, our distributors, and our customers. Thank you for the many years of support, and we look forward to serving you in the years to come.